Maintaining consistent quality in filter manufacturing requires comprehensive quality control measures throughout production. Even minor filter production equipment performance deviations can lead to product defects, increased waste, and dissatisfied customers. This guide explores several essential quality control strategies to help manufacturers achieve consistent, high-quality output while optimizing operational efficiency. From real-time monitoring to final product testing, each link is critical in ensuring your filters meet the highest industry standards. Manufacturers can significantly reduce production line variability by establishing a strong quality control protocol while improving overall equipment effectiveness and product reliability.

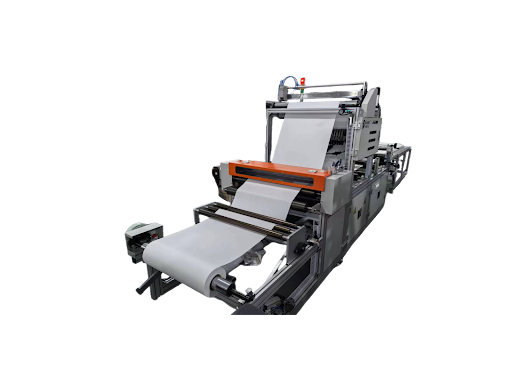

Implementing a Real-Time Monitoring System for Filter Production Equipment

Modern filter production equipment should use advanced IoT sensors and monitoring systems to track key operating parameters continuously. These systems monitor the operating temperature to prevent material degradation, vibration levels (which may indicate mechanical problems), production speed (to maintain a steady output), and differential pressure that affects filtration performance. The most effective monitoring solutions integrate directly with the MES to provide plant managers with a comprehensive dashboard showing real-time equipment status. When parameters deviate from established standards, the system immediately triggers an alarm, allowing operators to take corrective action before quality is affected. For best results, sensors must be regularly calibrated using certified reference standards to ensure measurement accuracy.

Standardize Maintenance Procedures to Ensure Equipment Accuracy

Developing and enforcing a strict maintenance procedure is critical to maintaining the accuracy of filter production equipment. A comprehensive maintenance program should include daily lubrication of all moving parts to reduce wear, weekly inspections of the sharpness and alignment of cutting blades and dies, monthly calibration of measurement systems to ensure dimensional accuracy and quarterly overhauls of critical components. Detailed maintenance logs document all service activities, replacement parts, and performance observations, providing valuable historical data for resolving recurring issues. Many advanced manufacturers have implemented computerized maintenance management systems (CMMS) that automate scheduling, track spare parts inventory, and generate predictive maintenance alerts based on equipment uptime and performance trends. These systems help maintenance teams prioritize tasks and ensure no critical maintenance activities are overlooked.

Material Quality Verification Before Production Begins

Implementing a rigorous material quality verification process ensures that only approved materials enter filter production equipments. First, incoming raw materials are thoroughly tested to confirm their key characteristics, including thickness consistency, porosity, and material composition. Adhesion performance requires special attention and verification of bond strength and cure time under production conditions. Proper storage of materials in a controlled environment prevents degradation due to humidity, temperature fluctuations, or UV exposure. A pre-article inspection procedure should be established for each new material batch, and initial production samples should be thoroughly tested before production begins. Leading manufacturers maintain detailed material certification databases to enable full traceability from raw material receipt to final product shipment.

Quality Inspections During Filter Production

Establishing multiple quality inspection points throughout the production process is critical to maintaining consistent output from filter production equipment. Automated visual inspection systems should be strategically positioned to continuously monitor surface defects, while laser measurement equipment is used to verify critical dimensional tolerances. Airflow test stations can be integrated into the production line to verify filter media performance at various stages of production. Weight checks ensure proper material distribution and consistency across production batches. Operator training programs should emphasize the importance of regular manual inspections and establish clear documentation procedures to record inspection results. The frequency of quality inspections should be increased when implementing sensitive product specifications or equipment adjustments. Advanced production facilities use SPC software that analyzes real-time production data to identify trends that may indicate equipment problems.

Final Product Testing and Performance Verification

A comprehensive final testing program ensures that each batch of filters meets specified performance standards before leaving the factory. Filter production facilities should have a fully equipped quality control laboratory capable of performing efficiency tests according to relevant industry standards. Pressure drop measurements verify airflow resistance characteristics, while structural integrity tests confirm durability under expected operating conditions. Accelerated life tests simulate long-term use to predict the product’s service life. Modern test equipment often has automatic data collection and reporting capabilities integrated with quality management systems. Many manufacturers have implemented automatic sorting systems that sort products into quality grades based on test results, ensuring that only qualified products are delivered to customers.

Build a Culture of Quality in Filter Production Equipment

A comprehensive quality ecosystem that integrates technology, processes, and people must be built to achieve and maintain stable output from filter production facilities. First, a strong real-time monitoring system should be implemented to provide visibility into equipment performance and standardized maintenance procedures to maintain machine accuracy. A rigorous material verification process ensures that only qualified inputs enter production, while strategically placed process checks identify potential problems early. Comprehensive final testing verifies product performance, meets specifications, and provides detailed traceability documentation.